Professional manufacturer of storage space

Chengdu Shelving Factory: What is the warehouse process?

Keywords:

Publish Time:

2025-07-24

The warehouse processes of Chengdu racking factory usually include the following main links:

Inbound process

- Receiving preparation: The purchasing department informs the warehouse in advance of the expected arrival time, quantity, and type of goods, and the warehouse personnel prepare for receiving, such as cleaning the storage area and preparing inspection tools.

- Goods inspection: When the goods arrive, the warehouse manager checks the quantity, specifications, model, and quality of the goods according to the purchase order or delivery note, ensuring that they are consistent with the order and have no damage or defects. Handle delicate, fragile, and valuable goods with care; strictly prohibit squeezing, collision, or inversion, and ensure proper storage.

- Inbound registration: After passing the inspection, the warehouse manager signs and confirms on the inbound form, and records the inbound date, batch, quantity, and storage location of the goods in detail. At the same time, the goods are placed according to the specified storage location, ensuring that they are classified and arranged neatly for easy management and retrieval.

- Account processing: Based on the inbound form, the warehouse manager promptly updates the inventory accounts, including manual ledgers and computer system records (if any), to ensure that the accounts and goods match.

Storage process

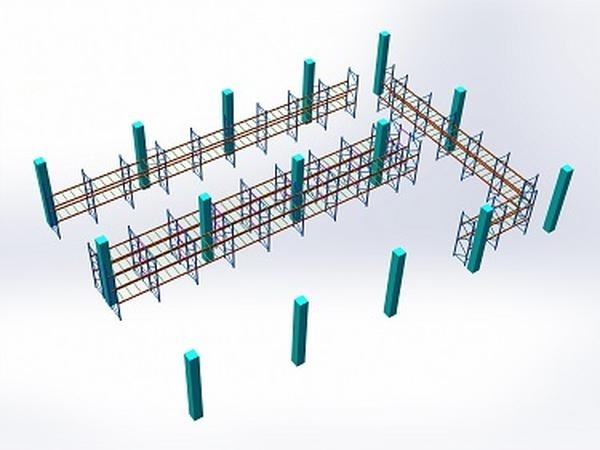

- Warehouse location planning: Based on the characteristics of the goods and the frequency of inbound and outbound operations of the racking factory, the warehouse is reasonably divided into zones and locations. For example, frequently used goods are placed near the entrance and exit, and heavier goods are placed on lower shelves.

- Goods storage: Regularly inspect the inventory for damage, deterioration, or loss, and keep records. Pay attention to temperature and humidity control, ventilation, moisture-proofing, and pest control in the warehouse to ensure a good storage environment.

- Identification management: Set up clear identification plates for each shelf and location, indicating the name, specifications, batch, and quantity of the goods for easy identification and management.

Outbound process

- Outbound application: When the production department or other departments need to receive goods, fill out an outbound form, indicating the name, specifications, quantity, receiving department, and recipient of the required goods, and submit it to the warehouse management department.

- Audit and preparation: The warehouse management personnel audit the outbound form. After confirmation, they prepare the goods according to the information on the outbound form, take the goods from the corresponding shelf location, and re-check the quantity and specifications of the goods to ensure accuracy.

- Outbound handover: After the goods are prepared, the warehouse manager hands over the goods and the outbound form to the recipient, and both parties conduct a handover, with the recipient signing for confirmation. At the same time, the warehouse manager signs on the outbound form and returns a copy to the relevant department for filing.

- Account update: Based on the outbound form, the warehouse manager promptly updates the inventory accounts, reducing the corresponding inventory quantity to ensure that the accounts and goods match.

Inventory process

- Regular inventory: Conduct a comprehensive inventory of the warehouse monthly or quarterly to verify whether the actual inventory is consistent with the account records. During the inventory, the warehouse manager counts the quantity of goods one by one and checks the condition of the goods.

- Irregular inventory: In addition to regular inventory, irregular inventory should be conducted as needed, such as after a large number of goods are moved in and out, or when warehouse management personnel change, to ensure inventory accuracy.

- Discrepancy handling: If discrepancies are found between the accounts and goods during the inventory process, the cause should be promptly investigated and handled accordingly. For surplus goods, the source should be investigated and recorded in time; for short goods, the cause should be analyzed. If it is normal loss, the disposal procedures should be handled; if it is caused by human error or theft, the relevant personnel should be held accountable.

Safety management process

- Safety facility maintenance: Ensure that the warehouse safety facilities are in good working order, such as fire-fighting equipment, anti-theft doors and windows, and monitoring equipment, and conduct regular inspections and maintenance.

- Safety operation standards: Formulate and strictly implement warehouse safety operating procedures, such as handling and stacking goods in accordance with safety requirements, and prohibiting smoking and using open flames in the warehouse.

- Personnel training: Regularly conduct safety training for warehouse personnel to improve their safety awareness and emergency response capabilities, and familiarize them with the use of various safety facilities and emergency plans.

Through the above series of scientific and rigorous process management, the warehouse of Chengdu racking factory can not only achieve efficient operation, but also effectively ensure the safety of goods and improve inventory accuracy. This is not only a strong commitment to customers, but also the key to the company's continuous optimization of supply chain management and enhancement of market competitiveness.

Hot Products

Related Articles