Professional manufacturer of storage space

Nanjing shelving factory, what is the shelf upright?

Keywords:

Publish Time:

2025-07-24

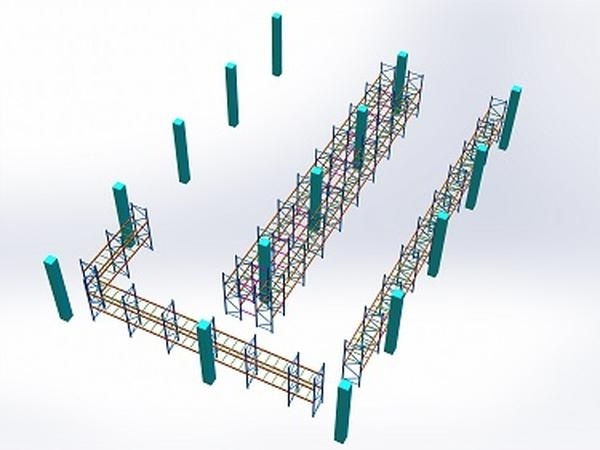

Upright columns are vertical components in Nanjing racking systems that support goods, primarily connecting upper and lower shelf beams to ensure the stability and load-bearing capacity of the racking system. The following is a detailed explanation of racking uprights:

Core Functions and Structural Features

- Functional Positioning: Rack uprights are the backbone support components of the racking system, bearing the weight of goods and transferring the load to the ground. Their stability directly affects the safety of the entire racking system.

- Structural Design: The surface of the uprights usually has perforations (such as diamond holes, butterfly holes, figure-eight holes, etc.) for connection with the beams. The hole spacing is mostly 50mm or 75mm, facilitating height adjustment. For example, the uprights of four-upright heavy-duty racking systems use diamond-shaped holes with a hole spacing of 50mm or 75mm, supporting vertical adjustment of the beams.

Common Types and Applicable Scenarios

- Two-Upright Racking: The most common type of heavy-duty beam racking, suitable for storing pallets and loose goods, with low cost and meeting conventional load-bearing requirements.

- Three-Upright Racking: Designed for large-sized and heavy goods, distributing weight more evenly, with stronger load-bearing capacity, and moderate cost.

- Four-Upright Racking: Non-standard customized versions of super heavy-duty racking, used in scenarios with extremely high load requirements (such as more than 4 tons per layer), offering optimal stability but higher cost.

Materials and Processes

- Material Selection: Primarily cold-rolled steel sheets and square/round steel pipes; some special scenarios may use polymer materials.

- Surface Treatment: Epoxy resin powder electrostatic spraying process is used to enhance wear resistance and corrosion resistance, while ensuring aesthetics.

Differences in Hole Types and Process Selection

- Diamond Holes: Require matching reinforced column clips; after installation, the column clips are pressed tightly to prevent shaking, but the flexibility is poor.

- Butterfly Holes: Easy to install, with good stability of column clip connection, commonly seen in medium-sized racking systems.

- Figure-Eight Holes: Commonly used in heavy-duty racking systems, saving space and having strong load-bearing capacity; column clip design can enhance stability.

The upright design of Nanjing racking factories emphasizes practicality and customization. The type and hole type of uprights should be selected according to the weight, size of goods, and warehouse requirements. It is recommended to prioritize products with mature processes and complete surface treatment to ensure long-term stability.

Hot Products

Related Articles